Swiss Partners

Bioburn AG, Zell (LU),

www.bioburn.ch,

Florian Studer

Project Type:

Technology:

Country:

Project Status:

Project Start:

End of Project:

Contract:

Documentation

Swiss Contribution

Bioburn is a Swiss social for-profit enterprise working in the renewable energy market. Bioburn® developed the internationally patented Bioburn® pelletizing technology that allows economic transformation of wet biomass into dry fuel pellets. The balance between economic, as well as social and ethical values is the corporate approach of Bioburn® for the realization of sustainable projects.

Description

The main goal of this project was to develop new ways of producing biofuel. This project implemented new technology of processing agricultural residual into biofuel-pellets and transferred proven Swiss technology to a new context in rural and peri-urban Uganda. It benefited from experience gained within the REPIC project “Sludge to Energy Enterprises in Kampala SEEK” (2014.05). Unused agricultural residuals have been transformed into marketable biofuel-pellets. The biofuel-pellets were produced on-site, where the biomass has been harvested and sold to peri-urban and urban areas. As the pellets have been locally produced, the project was to generate value in terms of employment and income, as well as providing people with cheap cooking fuel, while protecting forests from deforestation.

Results

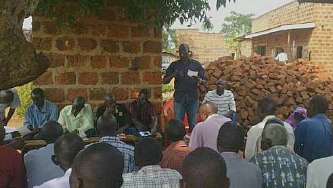

By the end of 2016, various biomass wastes were pelletized and tested in different combinations. Cocoa pods, which are also available in large quantities, proved to be the most promising material to use. In 2017, the first pelletizer was manufactured on site and the first pelletizing plant was successfully commissioned. The cocoa pod/coffee husk pellets produced in the first phase were successfully tested in various cookers. The new pelletizer met with lively interest at various workshops and trade fairs, as well.

However, the pelletizer’s trial run showed too much wear and tear on the machine, as well it being insufficiently robust. As a result, a more robust pelletizer was manufactured in Switzerland and its test operation began in Uganda. This new pelletizer’s technical feasibility was proven. Although, among other issues, there are still some open questions concerning the development of a competitive business model; partially due to the raw material which is free but still non-sustainable, and in some cases, illegally deforested fuel is also competes with the sale of pellets.

Impacts

Expected impacts, such as setting up a production chain and the creation of jobs, could not be realized within the project’s framework.